Building an Automated Test Jig: Requirements & References

Categories:

Summary

Here’s a list of design goals to guide the design of a series of related production test system. A list of interesting resources and and companies is included.

Introduction

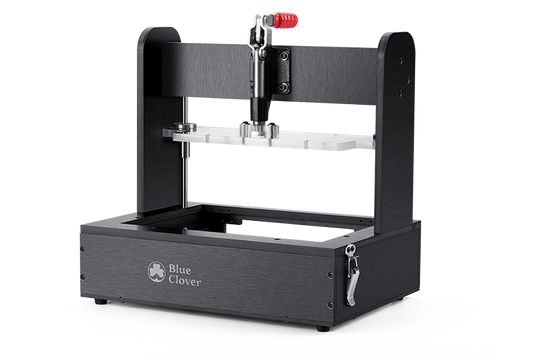

Blue Clover Tester Chassis

As the number of projects we’re supporting increases, the support requirements grow. There is a dire need of a standardized approach to test the electronics. Currently at Hobbs ElectroOptics and ElectroOptical Innovations we rely on standard flying probe bare board testing and automated optical inspection followed by built-in-self test. Some projects have a functional test stand which often also flashes the firmware. The aim then is to have a testing approach that is more fool proof and easier to transfer to a CM.

Requirements

- Adjustable: Allow test decisions to be delayed until late in the process. Ideally the design for test rules will allow all but the most critical tests to be worked out after the design is complete.

- Reusable & Standardized: Parts should be interchangeable as much as possible with the customization in the easily customizable parts. It’s okay to have 100 lengths of M3 screws, its less okay to rely on a custom die cast from a single source.

- Self explanatory: The design should scream its function. The operator should be able to figure out the operation without a manual.

- Minimum support: As this is end of project deliverable the device should be serviceable by other engineers. Custom electronics should be avoided is a COTS version exists. A data acquisition device should be used instead of integrating our own.

- Quick Turn: The device should be manufacturable with minimal handwork. Ikea style flatpack is fine, dead bug wired electronics is not.

- Interchangeable parts: This is related to standardization. Design in replaceable parts to avoid an entire system redesign. The form factor is relatively unconstrained so this should be straight forward.

- Mechanically Robust: Parts that wear out should be easily replaced. The design should not require the operator to be ultra careful to avoid breakage.

- Electrically Robust: Excellent ESD protection and EMI protection (or insensitivity). Ground loops should either not be possible or not effect the test.

- Compact: Should be easy to store and ship. There are secondary benefits to this such as being able to carry additional stock and keeping material cost low.

For the standard industrial method of doing this see National Instruments

Design For Test

The way I see it there are two classes of designs that use these jigs:

- Flexible: The design can support changes to increase testability.

- Inflexible: Either the design is already completed or its complexity such that it is better for the test system to carry some of the complexity.

Flexible designs can use more standard interfaces and even share jigs across similar projects. If the design is simple and the testing requirements are low, then a reusable or standardized jig may be ideal. Clamp fixtures, tag connectors, or the like may be a good option. The entire complexity of a formal test jig may not be required.

Clamp Fixture

Higher complexity flexible designs may use a standard layout of pads to speed up development plus sections of the jig to be reused. This could be done by designing a footprint or algorithmically placing pads with something like https://github.com/snhobbs/kicad-parts-placer. Placing pads by hand each time should be avoided.

Inflexible designs will need the fully custom jig. Complexity can be reduced by minimizing the number of pin types if possible. There are many ways to connect to features and a few design rules can ease complexity later. A single type of test pad, through hole, via, or pad should be used unless required. If a different pin or pitch is required this should be treated as a complexity and cost tradeoff. Major design changes like double sided testing should be treated similarly. See References & Resources: DFT Guides for DFT guides.

References & Resources

DFT Guides

- FixturFab: Design For Test

- Milwaukee Electronic: Designing a PCB Layout for Effective Board Testing

- Merifix: PCB Design Guide

- Altium: Assigning Testpoints on a PCB

- Altium: Design to Testability

- Bloomy: Design for Automated Testability

- JTAG: Board Design For Test Guidelines

- Electronic Design: Design for Testability and the Effects on Test-Fixture Fabrication

- Genesys: Design for Testability Guidelines

- Electronic Design: DFT—Almost 30, And Still Looking For Mainstream Adoption

- Electronic Design: What DFT Can Do for Your Products

- IPC APEX EXPO: Design for Testability (DFT) to Overcome Functional Board Test Complexities in Manufacturing Test

- Test Electronics: Design for Testability

- Altium Youtube: Test Points in High-Speed PCB Design

- FixturFab: Basic PCBA Design for Test (DFT) Guide

Terms & Definitions

- https://en.m.wikipedia.org/wiki/Bed_of_nails_tester

- https://en.m.wikipedia.org/wiki/In-circuit_testing

- https://en.m.wikipedia.org/wiki/Pogo_pin

Articles on Testing

- Electronic Design: PCB Testing Goes Socketless

- Electronic Design: Get On-Board ATE Test Fixtures

- Electronic Design: Reducing the Cost of Test in 2003

- Electronic Design: Built-In-Self-Test Gains Ground As ATE Time And Cost Soar

- Electronic Design: Test During Burn-In Is a Hot Topic. Although this is on IC testing and burn in, many of the ideas are transferable to PCBAs.

- Electronic Design: What Is Built-In Self Test And Why Do We Need It?

- Medium: PCB Inspection and Testing Techniques

Conferences

Example Usage & Projects

- Hackaday: https://hackaday.io/project/178776-functional-orange-test-fixture-based-on-fork

- TinyFPGA: https://www.crowdsupply.com/tinyfpga/tinyfpga-bx/updates/first-update-and-test-jig-development

- Connectorized Testing: https://www.youtube.com/watch?v=9paQYkpIbkc&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=12&ab_channel=VoltLog

- Reb Back Test Services: https://www.youtube.com/watch?v=yDfybZx02e0&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=5&ab_channel=EEVblog2

- Press Jig Example: https://www.youtube.com/watch?v=MpwVl5LJBy8&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=14

- Spark Fun: https://www.youtube.com/watch?v=v_THCk52WD4&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=8&ab_channel=SparkFunElectronics

- Clough42: https://www.youtube.com/watch?v=72RS6FlzNjI&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=19&ab_channel=Clough42

- Merifix: https://www.youtube.com/watch?v=NxxQZ3JyjiE&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=23&ab_channel=Merifix

- Test Electronics: https://www.youtube.com/watch?v=PduE2q3a35A&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=2

- Stephen Hawes: https://www.youtube.com/watch?v=MpwVl5LJBy8&feature=youtu.be

- Makers Mind: https://www.youtube.com/watch?v=gfpb1tH-m58&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=6&ab_channel=MakersMind

Guides & White Papers

- https://www.pcbway.com/project/share/PCB_testing_jig.html

- https://hackaday.com/2010/11/04/test-beds-and-jigs-with-pogo-pins/

- https://www.seeedstudio.com/blog/2021/06/18/7-most-popular-pcb-testing-methods-during-manufacturing-and-assembly/

- MadPCB Test Jigs: https://madpcb.com/test-jig/

- Choosing Probes: https://fixturfab.com/articles/selecting-test-probes-and-receptacles/

- Making test point csvs: https://fixturfab.com/articles/creating-test-point-csv-file/

- Process of testing #2: https://fixturfab.com/articles/functional-test-system-overview/

- FixtureFab Testing Webinar: https://youtu.be/YKuUM8z1n0Q

- FixtureFab designing a tester: https://fixturfab.com/articles/designing-a-3d-printed-development-fixture/

- MacroFab Small Test Fixture Code: https://macrofab.com/blog/fixture-code-final-testing-pcm5122-audio-dac/

- MacroFab Pogo pin Programming Cables: https://macrofab.com/blog/designing-pogo-pin-programming-cables-intro-tag-connect/

- MacroFab Programming Fixture: https://macrofab.com/blog/design-build-simple-programming-fixture/

- Polabs: What is PCB tester PoStep25-256 & How to test PCB with it: https://blog.poscope.com/pcb-tester/

- Robert Feranec & MagicDAQ: https://www.youtube.com/watch?v=fEQyW0qQFjk&list=PLQEimnUMDrgz9tN9Bt5nqfc9Cq5JrOmhh&index=18&ab_channel=RobertFeranec

Forums

- https://www.eevblog.com/forum/projects/test-jig-pcb-aligning/

- https://electronics.stackexchange.com/questions/358738/techniques-for-building-bed-of-nails-testing-board

- https://www.eevblog.com/forum/testgear/test-clip-that-latches-into-pcb-holes/

- https://pcmhacking.net/forums/viewtopic.php?f=42&t=6215&sid=4de2e1f85d6ee0f6bac79f82dafcbed4

Companies

- TheJigsApp: https://www.thejigsapp.com. Automatically generated test jigs for development, mid-scale manufacturing, and hardware-in-the-loop.

- BlueClover: https://bcdevices.com/. Mid scale focused full design services.

- FixturFab: https://fixturfab.com. Kits and full design services. Development, mid scale, & full scale test systems.

- Robson Technologies: https://www.testfixtures.com/. Full design services, mid scale & full scale focused.

- Ingun: https://ingun.com/en-GB/. Full automotive style production focused. Sells all parts off the shelf.

- Merifix: https://store.merifix.com/. Development focused complete test jig kits.

- Coda-Pin: https://coda-systems.co.uk/. Development, mid scale & full scale production complete test jig kits, parts.

- Mill-Max: https://www.mill-max.com/. Pogo pins & reliable connectors

- Harmond: https://www.harwin.com/connectors-hardware/spring-contacts/. Pogo pins & ATE probes

- Test Electronics: https://testelectronics.com/. Design services, test jig kits. Development & mid scale focused.

- Red Back Test Services: https://www.redbacktest.com.au/. Design services, mid and full production.

- Columbia: https://www.columbia.se. Design services, mid and full production.

- Test Head Engineering: https://www.testhead.com/products/functional-test-fixtures/. Design services, mid and full production.

- Equip Test: https://equip-test.com/test-fixture-kits.php. Fixtures, probes, test electronics, EMI shielded fixtures. Mid and full production as well as high value development.

- Misumi: https://us.misumi-ec.com/. Wide selection of custom test jig hardware.